|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

ELECTRICAL

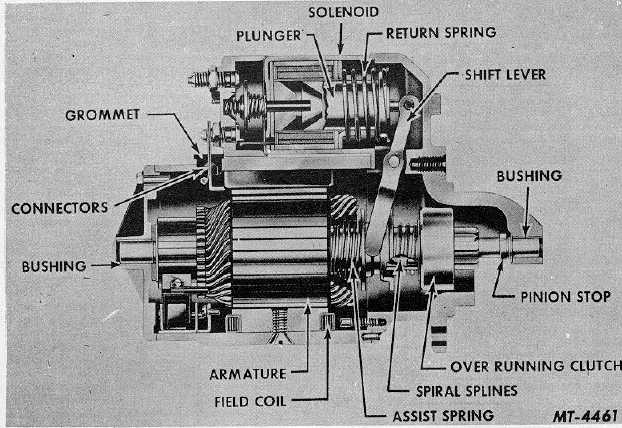

Fig. 1 Sectional View of Enclosed Shift Lever Type Starting Motor

DESCRIPTION

The enclosed shift lever type starting motor is equipped

with a drive end housing which encloses the entire shifting

mechanism and solenoid plunger, protecting them from road

dirt, splash and icing conditions.

The solenoid is mounted on the flange of the drive end

housing and operates the overrunning clutch drive by means

of a linkage and shift lever. When the control switch closes

the starting circuit the solenoid is energized shifting the pinion

into mesh with the ring gear on the engine flywheel and

closing the main contacts inside the solenoid. When the

contacts inside the solenoid close, battery current is then

supplied to the motor causing the armature to rotate. Torque

is then transmitted by the clutch from the starting motor

armature to the flywheel. To protect the armature from

excessive speeds when the engine starts the clutch is

designed to "overrun" or

turn faster than the armature which permits the pinion to

disengage itself.

LUBRICATION

Some starting motors require no lubrication except at

overhaul, while other motors are equipped with lubrication

fittings. The motor should be lubricated every 8000 km (5000

miles) or 300 hours of operation if a means of lubrication is

provided.

1.

Hinge cap oilers or oil tubes sealed with pipe plugs

should have 8 to 10 drops of medium grade engine oil.

2.

Grease cups should be turned down one turn or refilled

if necessary.

If the motor is disassembled for any reason lubricate as

follows:

1.

Oil wicks should be resaturated if equipped.

CTS-2258N Page 3

PRINTED IN UNITED STATES OF AMERICA

|