|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

ELECTRICAL

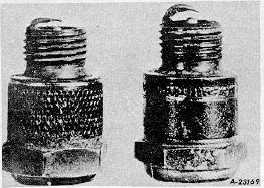

has become worn away or the ground electrode has become

so badly eroded at the sparking area that resetting of the gap

is either difficult or impossible, the spark plug is not fit for

further efficient engine service--even if cleaned.

Fig. 17 Condition of Electrodes

CLEANING AND SETTING

Remove spark plug gaskets if plugs are to be cleaned.

Remove oily deposits from both firing end and outside

surface of plug using a commercial cleaning solvent which

dries quickly. Failure to remove oil from spark plugs will

result in cleaner abrasive packing inside the firing end of

spark plug if an abrasive type cleaner is used.

Use the instructions provided with the liquid spark plug

cleaner and tester (SE-2190) and be sure the plugs are

thoroughly dry before testing.

If an abrasive type plug cleaner is used, be sure the

spark plugs are free of abrasive material before testing.

Pass a thin point file between center and ground

electrodes to smooth up both surfaces.

Reset gap by moving ground side electrode only. Do

not touch center electrode, as insulator tip fracture may result.

Bend ground electrode toward center electrode.

Using a wire feeler gauge, gap plugs to specifications.

A very slight drag should be felt when feeler gauge passes

between electrodes.

Use the instructions provided with the tester to check

spark plugs.

NOTE:

Never assume you are simulating cranking

compression when using the tester. Air

pressure in a bench tester has no direct

relation to engine compression for the

following reasons:

1.

There are no temperature effects in the bench

test. Heated electrodes within warm cylinders in an

engine require less voltage than under a cold bench

test.

2.

There is no fuel/air charge in the bench tester.

3.

Since spark plug firing is dependent on engine timing,

firing of the spark plugs is not always at the point of

maximum compress ion.

4.

There is no cylinder turbulence in the tester pressure

chamber.

Because of these variables, the bench test, while

useful, cannot be measured by any specific psi readings.

HEAT RANGE

Spark plug heat range is the primary factor governing

spark plug performance under various service conditions.

The term "heat range simply refers to the classification of

spark plugs according to their ability to transfer heat from the

firing end of the plug to the cooling system of the engine.

The rate of heat transfer, or heat range, is controlled

basically by the distance between the inside gasket seat and

the insulator tip.

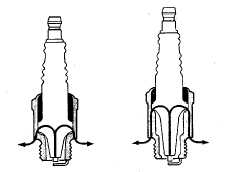

A "cold" type plug, Fig. 18, has a relatively short

insulator nose and transfers heat very rapidly into the engine's

cooling system. Such a plug is used in heavy-duty or

continuous high speed operation to avoid overheating.

MT-3754

Fig. 18 Construction and Heat Flow of "Hot” and "Cold"

Plugs

The "hot" type plug, Fig. 18, has a much longer

insulator nose and transfers heat more slowly away from its

firing end. Thus, it runs hotter and burns off combustion

deposits which tend to foul the plug during prolonged idle or

low-speed operation.

CTS-2016-J Page 7

PRINTED IN UNITED STATES OF AMERICA

|