|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

5.

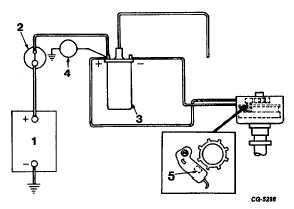

Test primary voltage.

"Bump" starter to position sensor coil between two

trigger wheel teeth (see Figure 50).

Connect voltmeter between coil positive (+) terminal

and ground. Turn ignition switch "on" and observe

voltmeter. If voltmeter reads battery voltage (12-

13V), proceed to step 6.

If voltage is noticeably lower than battery voltage, a

high resistance exists between battery (through

ignition switch) and coil which must be located and

repaired. (See Primary Voltage Drop Test).

Fig. 50 Testing Primary Voltage

1. Battery

4. Voltmeter

2. Ignition Switch

5. Sensor Coil Between

3. Ignition Coil

Two Trigger Wheel

Teeth

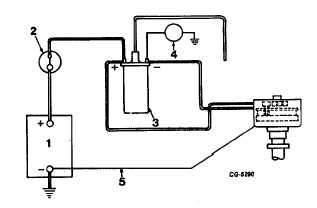

6.

Test voltage at coil negative (-) terminal.

Sensor coil should be between two trigger wheel

teeth. Connect voltmeter between coil negative (-)

terminal and ground (Figure 51).

With ignition switch "on", one of the following

voltmeter readings will be obtained: (A) 5 to 8 volts

(normal) (B) 12 to 13 volts (problem area) (C) 0 to 5

volts (problem area)

A.

If voltage is 5 to.8 volts:

Proceed to Step 7.

B.

If voltage reading is 12 to 13 volts:

Connect jumper wire between distributor housing and

battery negative (-) terminal (Figure 52). Observe

voltmeter.

Fig. 51 Testing Voltage at Coil Negative

(-) Terminal

1. Battery

3. Ignition Coil

2. Ignition Switch

4. Voltmeter

If voltage remains at 12 - 13 volts, electronic control

unit in distributor is faulty and must be replaced.

If voltage changes to 5 - 8 volts with jumper wire

connected, a problem exists in the ground circuit

between the distributor and the battery. Check

battery negative (-) cable (at battery and engine) and

cab-to-engine ground strap and/or other ground

straps. Repair as needed.

Fig. 52. Testing With Jumper Wire Between Dist. Housing

and Batt. (-) Terminal.

1. Battery

4. Voltmeter

2. Ignition Switch

5. Jumper Wire

3. Ignition Coil

CGES-145-U Page 25

PRINTED IN UNITED STATES OF AMERICA

|