|

| |

ENGINE DIVISION SERVICE MANUAL

TM 5-4210-230-14&P-1

CLEANING AND INSPECTION

1.

Wash metal parts in cleaning solvent.

IMPORTANT

Do Not wash cap, rotor, vacuum advance

diaphragm assembly or electronic control unit.

It is permissible to soak the distributor housing if

the bushings are to be replaced. If bushings are

not to be replaced, clean distributor housing

carefully so as not to wash oil from bushings.

2.

Inspect distributor shaft for wear and check its fit in

bushings in distributor housing. If shaft and bushings

are worn, replace them.

3.

Mount distributor shaft in "V" blocks and check shaft

alignment with dial indicator. Runout should not

exceed 0.05mm (.002").

4.

Inspect mechanical advance weights for free fit on their

pivot pins and in slots of trigger wheel yoke without

excessive looseness. If wear or damage is found,

replace distributor shaft assembly.

5.

Inspect trigger wheel teeth for damage. Check fit of

trigger wheel assembly on distributor shaft. It should

be free without roughness. If roughness or excessive

looseness exists, replace distributor shaft assembly.

6.

Inspect sensor advance plate of electronic control unit.

1. binding or wear of pivot pin is indicated, replace

control unit assembly.

7.

On

distributors

with

tachometer

drive,

inspect

tachometer drive parts. (See Tachometer Drive

Service).

8.

Inspect rotor, distributor cap and high tension cables.

(See Secondary Circuit Inspection Under IGNITION

SYSTEM TROUBLE SHOOTING TEST.)

DISTRIBUTOR HOUSING BUSHING REPLACEMENT

The following procedures can be followed to remove

and replace the distributor shaft bushings in the distributor

housing. Distributor tool set SE-1955 will assist in performing

these operations.

Illustrations show bushing removal and installation

operations being performed on distributor without tachometer

drive. Procedures for distributors with tachometer drive are

similar.

Bushing Removal

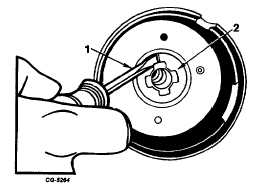

1.

On distributors without tachometer drive, use a small

screwdriver to pry upper bushing grease retainer

washer from distributor housing (Figure 23).

Fig. 23 Removing Grease Retainer Washer (Distributors

Without Tachometer Drive)

1. Screwdriver

2. Grease Retainer

2.

On distributors for V-537 engine, use a screwdriver to

pry oil seal out of lower end of distributor housing

(Figure 24)

CGES-145-U Page 12

PRINTED IN UNITED STATES OF AMERICA

|