|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

the inside wheel is driven at ring gear speed while the

outside wheel is driven by the ground faster than ring

gear speed. When the rearward turn is nearing

completion and the vehicle is slowing down because of

application of the brakes, the outside wheel is driven by

the ground at ring gear speed, as its driven clutch

member is fully engaged and acts to "brake" against the

engine torque. The inside wheel is driven by the ground

through the smaller arc of travel, and since its driven

clutch member is disengaged, it will rotate slower than

ring gear speed.

Fig. 42 shows the operation of the differential

when a right-hand turn in a rearward direction is being

negotiated.

DIFFERENTIAL REMOVAL

The procedure for removing the differential is

the same as used for a conventional differential.

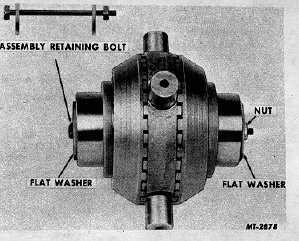

IMPORTANT PRECAUTION: Before disassembling the

differential case, insert a bolt through the center of the

NoSPIN unit (axle shaft openings) with a flat washer on

each end against the side members, Fig. 43.

Thread a nut on the bolt against the flat washer

finger tight. This will prevent possible injury caused by

the unit flying apart due to the spring pressure within

itself during disassembly of the differential case.

Fig. 43 Inserting Assembly Retaining Bolt

DISASSEMBLY

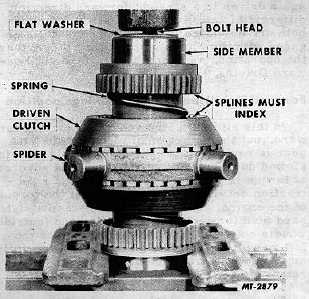

Remove the bolts from the differential case and

lift out the NoSPIN unit. Mount unit in a small press,

Fig. 44.

Apply enough pressure on the head of the bolt

to release the spring pressure against the nut. Remove

the nut and flat washer by reaching

underneath the press. Slowly release the press and

allow the unit to disassemble itself until the spring

pressure is fully released.

Remove unit from press.

Fig. 44 Release of Spring Pressure

Remove

side

members,

springs,

spring

retainers and driven clutch members. The center cam

may be removed from the spider by expanding the snap

ring with small screwdrivers or wedges.

NOTE:

Be

careful

when

removing

and

reinstalling center cam snap ring to avoid possible

injury.

CLEANING, INSPECTION AND REPAIR

Wash all parts thoroughly with a cleaning

solvent. Inspect all mating surfaces and teeth for

possible wear or damage. Replace all worn or damaged

parts before reassembly.

REASSEMBLY

Reassembly is essentially the reverse of

disassembly. Lubricate all parts with SAE-30 oil during

reassembly. Place side member upright and install

spring on same. Place spring retainer on spring with

flange end toward side member. Install driven clutch

member on spring retainer. Place spider on driven

clutch member, indexing teeth of same. Install other

driven clutch member, spring retainer, spring and side

member on spider.

Insert a bolt through the center of the NoSPIN

unit with a flat washer against side

CTS-2095S - Chapter II - Page 6

PRINTED IN UNITED STATES OF AMERICA

|