|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

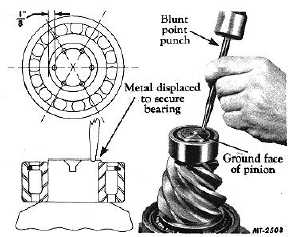

If the pinion radial or straddle bearing was removed

from the end of the pinion during the disassembly, the bearing

should be reinstalled at this time. Press the radial bearing

onto the end of pinion and stake with a blunt point punch, as

shown in Fig. 24, in six equidistant places. It is suggested

that for locating punch positions for staking, the end of the

pinion be painted with Prussian Blue and a circle be scribed

on end of pinion about 3.175 mm (1/8") in from the pinion

circumference. When staking the bearing, be careful to make

the depth of the indentations or stake points uniform.

Otherwise, the bearing might be damaged. Deep punch or

stake marks are not necessary. Apply the staking operation

at opposite sides of the pinion end until all stake points are

obtained.

NOTE

Smaller pinions having the straddle bearings

are staked in four places only. Where special

staking tools are available, they can be used;

otherwise, the use of a blunt or round-nose

punch is satisfactory.

Fig. 24 Staking Pinion Straddle Bearing

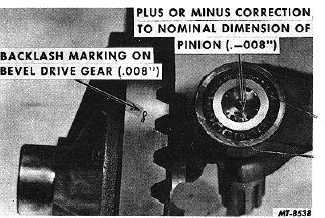

ESTABLISH NOMINAL DIMENSION

The pinion setting gauge (SE-1065) is a precision

gauge designed for locating the pinion as it meshes with the

ring gear to the correct nominal dimension in the shortest

possible time. A step plate and bracket, which are a part of

the set, are used whenever hypoid type gears are to be

adjusted. Essentially the pinion setting gauge is a direct

reading depth micrometer mounted in an arbor. The span of

the micrometer is 50-75 mm (2" to 3"), but extensions are

provided with the kit to increase the reach. Two sleeves which

hold adapter discs slip over the ends of the arbor. Adapter

discs are held on the sleeves by knurled nuts. When installed

in the differential case, the pinion setting gauge enables the

mechanic to measure the distance from the face or finished

end of the installed pinion to the centerline of the ring gear or

cross shaft. The measurement which the mechanic reads

should agree with the nominal dimension, which can be found

in the axle specifications, or which in some instances is

stamped or etched on the pinion itself. Usually there is a plus

or minus correction also stamped on the pinion, Fig. 25, and

this also must be figured in with the nominal dimension.

Fig. 25 Location of Pinion Setting Markings

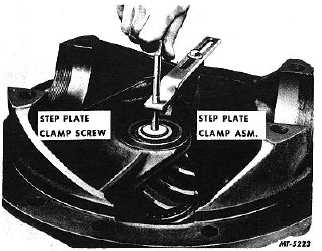

The procedure for establishing the correct nominal

dimension by means of the pinion setting gauge is as follows:

1.

Install pinion, cage and bearing assembly in the

differential carrier.

2.

Attach the step plate clamp assembly to the carrier

flange and locate step plate clamp screw over the

center of the pinion as shown in Fig. 26.

Fig. 26 Locating Step Plate Clamp

3.

Install step plate under clamp screw and tighten

screw to hold the step plate securely in position as

shown in Fig. 27. The step plate is necessary in

order to project the face of the pinion to where it can

be measured by the gauge which is on the centerline

of the ring gear.

NOTE

Be sure

CTS-2095S-CHAPTER I-Page 11

PRINTED IN UNITED STATES OF AMERICA

|