|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

AXLE-FRONT

USE FINGERS ONLY TO TURN CONTROLS. If controls do

not turn freely with your fingers, move the vehicle either way a

few inches in 2-wheel drive standard gear range to relieve

pressure against the gears. If hubs do not now turn freely,

look for external damage.

SERVICING

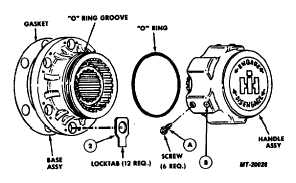

This locking hub is serviced in two major assemblies, namely,

a clutch half and body half. Individual components are not

provided. Refer to Scout Parts Catalog when ordering.

DISASSEMBLY

1.

With handle in disengage position, remove handle

assembly by removing the three screws "A". Do not

remove the three screws "B".

2.

If screws "B" are removed, misalignment could occur

on reassembly causing damage to cam. There is no

reason to ever remove screws "B".

3.

Remove and retain retaining ring on axle.

4.

Remove base assembly, by removing six bolts.

5.

If locktabs were used, the tabs must be bent out of

the way of the bolt head.

6.

Clean gasket surfaces thoroughly.

7.

Wipe the axle spline clean and lubricate.

REASSEMBLY

1.

Install the base assembly with new gasket in place,

to the vehicle hub.

2.

Secure base assembly to vehicle with bolts and new

lock tabs.

3.

The tab on the locktab is to be bent up against flat on

head of bolt to insure against loosening.

4.

Install retaining ring on axle shaft.

5.

Install new "O" ring into groove on base assembly.

6.

Apply thin film of grease to "O" ring, prior to installing

handle assembly.

7.

Place the handle assembly in position.

8.

With the splines of the sliding gear aligned with the

splines within base, push the handle assembly on the

base.

9.

Using hand pressure, compress the spring enough to

allow the screw holes for screws "A" to line up with

the groove in base.

10.

Insert three new screws "A". DO NOT FORCE.

Screws must enter and screw into place freely.

TORQUE SPECIFICATION

Torque hub assembly mounting bolts to 32-40 ft. lbs. 43-54

N-m.

CTS-2785 CHAPTER III Page 3

PRINTED IN UNITED STATES OF AMERICA

|