|

| |

TM 5-4210-230-14&P-1

TRUCK SERVICE MANUAL

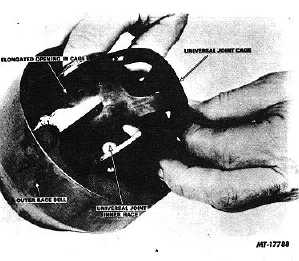

the two elongated openings in cage aligned with

opposite teeth of outer race bell (Fig. 12). Lift cage and

inner race from outer race bell.

Fig. 12 Removing Cage and Inner Race

4.

To separate inner race from cage turn inner race at

right angle to cage, align notched tooth of inner race

with elongated opening in cage, and roll inner race out

of cage.

Cleaning and Inspection

Remove all dirt, old lubricant and gasket material from

all components. Immerse in cleaning solvent and use a stiff

brush if necessary. Bearings should be cleaned separately in

clean solvent and special efforts taken to protect their finely

machined surfaces. If compressed air is used for drying, do

not spin bearings while drying.

Examine all bearings for roughness, damage or wear

by rotating each bearing slowly in the hand. If in doubt as to

bearing condition, replace.

Inspect axle shaft and universal joint assembly for

seizure, broken or chipped balls, broken splines or other

damage

Inspect spindle bushing for out of round condition

caused by wear or corrosion, scoring or roughness in spots.

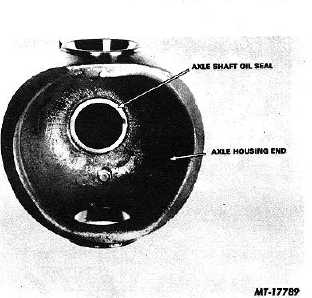

Inspect axle shaft oil seal for evidence of wear or

damage.

Inspect for evidence of wear due to improper drive

flange shim size. Wear on the interior surface of ball end of

axle housing and on edge of ball joint bell housing indicates

the use of too thin a shim, allowing contact between the two.

If shim is too thick, the spindle bushing will show excessive

wear.

Oil Seal and Bearing Replacement

1.

To replace axle shaft oil seal (Fig. 13) pry out old seal

from bore of axle housing and discard. Install new

seal. Seal must contact counterbore.

Fig. 13 Axle Shaft Oil Seal

2.

To remove upper and lower trunnion bearing cups,

drive cups out of axle housing bores with a driver and

brass drift inserted through the opposite bore (Fig. 14).

When installing new trunnion bearing cups care should

be taken not to nick or scar bearing mating surface of

cup.

Cups and bearings should be replaced as a matched

set.

3.

To remove spindle bushing (Fig. 15) insert puller in

bushing bore and extract old bushing and discard.

Install new bushing in bore. Bushing must contact

counter bore.

CTS-2658S Page 16

PRINTED IN UNITED STATES OF AMERICA

|