|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

WHEELS, RIMS, TIRES

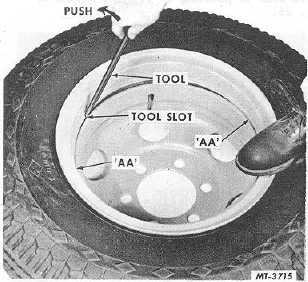

Fig. 27

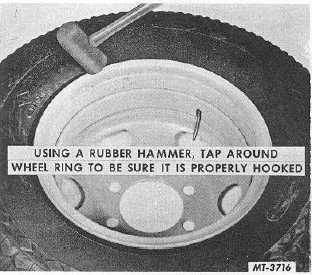

Using a rubber hammer tap around wheel (side) ring to

be certain it is properly seated (Fig. 28).

Fig. 28

When side ring is properly installed on rim, it is loose.

If side ring cannot be moved, the ring is binding.

CAUTION!

TO PREVENT POSSIBLE BODILY INJURY

caused by the wheel side ring being blown off with extreme

violence during inflation, DO NOT stand unprotected in front

of side ring when inflating tire. If no protection device is

available, stand wheel and tire close to a solid wall with side

ring facing the wall. Inflate tire from side opposite ring. If no

solid wall is available place tire and wheel on floor with side

ring next to floor (down) and inflate from above keeping body

AWAY from directly in front of or above tire at all times. See

Precautions, Chapter I.

Inflate tire until tire beads are firmly seated against rim

flanges. CAUTION: Never inflate above 40 psi to seat beads.

Completely deflate tire by removing valve core; then reinflate

tire to recommended pressure.

Refer to "Operator's Manual" for recommended inflation

pressures. /

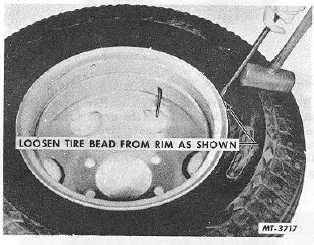

Fig. 29

To remove side ring from a new rim, spread the rim

and side ring apart. Insert tool in the tool slot and pull tool to

the left. After side ring starts to lift over lip, remove ring from

rim (Fig. 29).

MOUNTING NUTS (Disc Wheels)

Where Standard automotive type disc wheels have

been used in the past, both left and right hand threads will be

found at the wheel mounting studs and nuts. Common

practice has been to use left-hand threads at the left-hand

wheels and right-hand threads at the right side of the vehicle.

This was done to assure keeping wheel mounting nuts tight.

CTS-2032N Page 10

PRINTED IN UNITED STATES OF AMERICA

|