|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

WHEELS, RIMS, TIRES

Fig. 7

NOTE: Rust streaks (Fig. 8) from stud holes is a good

indication that mounting nuts are not tightened to the specified

torque.

Fig. 8

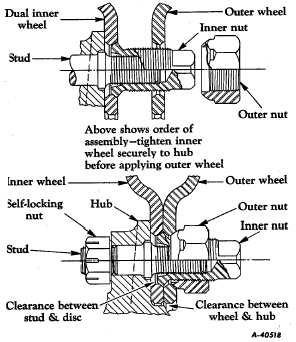

DISC WHEELS

On disc wheels, which have rims integral with the

wheel itself, the important thing to note is that the wheel stud

nuts must be kept tight. This means they should be inspected

and tightened at regular intervals. When checking the

mounting studs and nuts on dual disc wheels,

(Fig. 9) the outer nut should be backed off before attempting

to tighten the inner nut. Try all cap nuts after the first trip or

any wheel change. Properly installed they should remain tight

indefinitely. On cast wheels which have rims that are

demountable with the tire, the rim clamp nuts should also be

kept tight. Rim and tire to wheel alignment should be checked

frequently to make sure the tire is running true. Left-hand

thread nuts can be identified by the small groove machined

around the flats. Left hand studs can be identified by the

letter "L" stamped on the head. Use left-hand nuts on the left

side of the truck.

Fig. 9

NOTE: Before mounting wheel assemblies on vehicle

make sure all parts are clean and free from foreign matter.

Excess paint on wheel stud hole perimeters can permit wheel

mounting nuts to loosen with use.

RIM TIGHTENING AND ALIGNMENT

When installing demountable rims, be certain stud

threads are clean to permit correct torquing of nuts. NOTE:

Do not use any type of lubrication on threads except when

installing aluminum wheels.

With rims in position (valve stem 180 degrees apart)

successively tighten opposite nuts to assure drawing wheel

(or wheels in evenly. This procedure will also minimize wheel

mis-

CTS-2032N Page 3

PRINTED IN UNITED STATES OF AMERICA

|