|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

WHEELS, RIMS, TIRES

CHAPTER I

WHEELS

GENERAL

The information presented herein covers factory installed wheels and hubs for medium and heavy duty vehicles. Many types

of wheels are available and they vary in size, types (disc or cast) and materials (steel or aluminum). Fundamentally, they are the

same in that all wheels (or hubs for disc wheels) are mounted to the axles on tapered roller bearings.

SAFETY PRECAUTIONS

Always deflate tires completely before removing locks or side rings.

Always inspect and clean all parts before assembly.

Always inflate tires in safety cage.

Always use a "clip-on" air chuck with remote valve to inflate tires.

Never mix parts of different types or size.

Never use cracked, bent or badly rusted parts.

Never reinflate flat tire on vehicle--use the spare.

Never add air until certain each side or lock ring is fully seated.

WHEEL BEARING ADJUSTMENT

Satisfactory wheel operation and long bearing life

depends on correct wheel bearing installation, lubrication and

adjustment. The following will help you perform these

required services for wheels and hubs.

FRONT WHEEL BEARINGS

Wheels or hubs, bearing cups, nuts, locks, hub caps,

shafts and spindles are to be free from any foreign matter.

Bearing cones must be properly packed with specified

lubricant if wheels are grease packed (see LUBRICATION,

Section

If wheel bearings are oil lubricated dip bearing cones in

lubricant to provide proper starting lubrication. Outer surface

of bearing cone and matching surface of cup may be coated

with lubricant to promote cone-to-cup adhesion and facilitate

assembly.

After wheel (or hub) and bearings are assembled in place on

the spindle, tighten the wheel bearing adjusting nut to 69 N•m

(50 ft lbs) while rotating the wheel. Then back off the nut 1/4

turn. If the lock or cotter key can be installed at this position,

do so; if not,

tighten to the nearest locking position and insert new key or

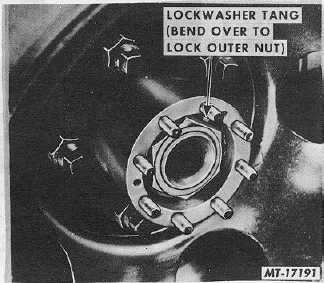

lock. Bent type lockwasher is to have one tab bent over the

adjusting nut. For axles that have double nut type lock,

tighten jam nut to 136-203 N•m (100 -150 ft lbs) and bend one

tab of the lockwasher over the jam nut (Fig. 1). These

procedures are intended to result in zero to .25mm (.010") end

play with no preload.

Fig. 1

CTS-2032N Page 1

PRINTED IN UNITED STATES OF AMERICA

|