|

| |

TRUCK SERVICE MANUAL

TM 5-4210-230-14&P-1

TRANSMISSION

20. Install gear spacer on shaft and then install Lo gear with

long hub toward outside (front) of case.

21. With shaft in 'position, install rear bearing cup in case.

Use a new gasket and install rear bearing cap,

lockwashers and capscrews Tighten capscrews to

specified torque.

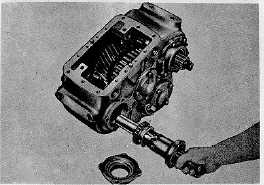

22. Drive front bearing onto idler shaft. Hold shaft rigid to

avoid damaging rear bearing and cup (Fig. 34). Install

bearing retainer plate and capscrews. Lock wire.

Fig. 34.

23. Tap front bearing cup into place.

24. Install sufficient shims to set up end play in idler

assembly. Install front bearing cap and secure with

capscrews and lockwashers.

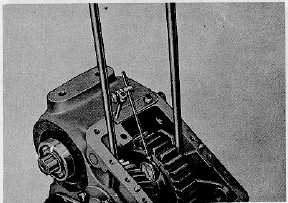

25. Mount a dial indicator on case with stem set against

inside face of Lo gear. Check the amount of end play by

working assembly back and forth with two prybars as

shown (Fig. 35). Remove sufficient shims to arrive at a

bearing adjustment of .076 mm .127 mm (.003" - .005")

end play.

Fig. 35.

Fig. 36.

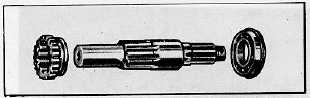

26. Install ball bearing on front output shaft with bearing snap

ring toward outside.

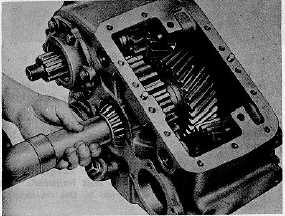

27. Install sliding collar on shaft. Slide shaft into case (Fig.

37).

28. With shaft in position, install a new gasket, bearing cap

and oil seal, lockwashers and capscrews. Tighten

capscrews to specified torque.

29. Position a new gasket and then mount backing plate,

deflector and stamped washer. Insert capscrews and star

washers and tighten to specified torque (Fig. 38).

30. Position brake lever on backing plate.

31. Position brake shoes on backing plate with actuating pawl

in web slot (Fig. 39).

32. Hook up brake shoe return springs.

33. Slide brake hub over splines of front output gear. Install

retaining ring (Fig. 40).

Fig. 37.

CTS-2048Q Page 12

PRINTED IN UNITED STATES OF AMERICA

|