|

| |

TM5-4210-229-14&P

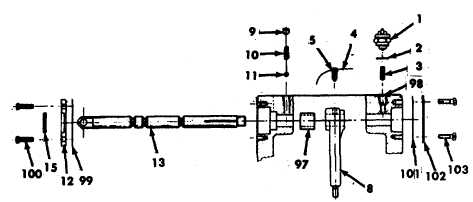

6-18. TRANSFER CASE REPAIR (Continued).

(9)

Coat the seal surface area and the splines

with Lubriplate (Appendix D, Item 34). Install

the yoke on the front of the input shaft.

Lightly coat one side of the retaining washer

(93) with sealant (Appendix D, Item 47) and

then install it onto the shaft with the coated

side facing the input yoke. Install the yoke

retaining locknut (94) and torque it to 300 ft-lb

(406.80 N.m).

(10) Temporarily install the input shaft rear cap

(16) without shims (95) and torque bolts (96)

to 25 ft-lb (33.90 N.m). Measure the gap

between the input shaft rear cap (16) and the

case housing. Select a shim stack that is 0.0

10 to 0.005 in. larger than the gap dimension

measured. Remove the cap (16) and then

install the selected shims (95) and reinstall

the cap. Coat the bolt threads with sealant

(Appendix D, Item 47), install and torque bolts

(96) to 45 ft-lb (61.02 N.m).

f.

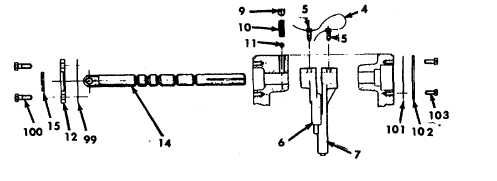

Shifter shafts assembly.

NOTE

There are three shift forks used in this transfer

case. Each shift fork is a different length.

(1)

Insert the shift shaft (14), the one with 5

grooves, into the shift shaft hole next to the

input shaft until the shaft is visible through the

cover opening. Position the direct drive

clutch shift fork (6) (5-7/8 inches long) into the

groove in the clutch on the input shaft with the

long hub portion of the shift fork facing the

front of the case. Slide the shift shaft through

the shift fork just enough to

clear the underdrive shift fork (7) (7-5/8 inches

long). The underdrive shift fork (7) should be

installed at this time with the hub portion of

the shift fork facing the rear of the case and

the forked end into the groove in the clutch on

the intermediate shaft. Slide the shift shaft

through this fork and into the hole on the back

of the case.

(2)

Align the retaining screw hole on the

underdrive shift fork (7) with the rear-most

groove in the shift shaft. Install the shift fork

set screw (5) into the fork. Position the flat

face of the eye end of the shift shaft paralleled

to a line through the input and rear output

shaft centerlines in order to put the flat side in

a vertical plane on the installed case. Torque

the shift fork set screw to 25 ft-lb (33.90 N.m).

(3)

Slide the direct drive fork (6) and clutch to

position the fork set screw hole over the next

shift shaft groove and install set screw (5). To

insure

maintenance

of

fork-to-clutch

clearance, hold the two shift forks in either

clockwise or counterclockwise direction and

then torque set screw. Torque set screws (5)

to 25 ft-lb (33.90 N.m)and lockwire (4).

6-103

|