|

| |

TM5-4210-229-14&P

6-12. PISTON AND CONNECTING ROD MAINTENANCE (Continued).

CAUTION

It is advisable to wrap an oil-soaked cloth

around the crankshaft connecting rod

bearing journals to keep them as clean as

possible. Wrap the piston and connecting

rod assemblies in clean cloth also to protect

them until installation.

b. Remove the connecting rod bolts from the rod

caps and remove the caps and bearing inserts

from the rod ends. Keep in order and observe

markings to prevent mismatching.

c. Push the connecting rod and piston to the top of

the cylinder and remove them from the top of

the crankcase with extreme care.

d. Crank the engine by hand and remove all of the

remaining pistons as outlined. Be sure to re-

place each bearing cap on its respective con-

necting rod after removal of the piston from

the engine.

e. Cylinder sleeve removal.

(1) After piston and rod removal use the uni-

versal wet sleeve puller and remove cylin-

der sleeves.

(2) Position the puller in the sleeve. Hold the

jaws of the puller and turn the screw, which

spreads the jaws to grip the edge of the

cylinder sleeve. Tighten the locking bar

against the top of the sleeve.

(3) Turn the bearing-mounted forcing nut to

break the cylinder sleeve loose from the

crankcase.

CAUTION

If more than one sleeve is to be removed and

they are to be used again, it is important that

the sleeves be marked with the cylinder num-

ber they were removed from.

(4) Remove the sleeve; if necessary thread a

slide hammer into the forcing screw to aid in

removal.

f. Connecting rods, pistons and rings disassembly.

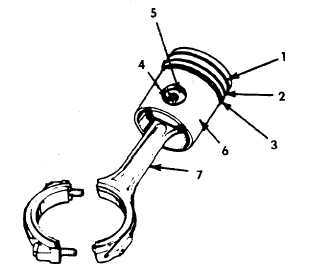

(1) Remove the piston rings (1, 2, and 3) with a

piston ring expander. Remove the top com-

pression ring first then the remaining rings

in order.

(2) Remove the piston pin retainers (4) from

each piston.

CAUTION

Do not apply excessive force to the piston pin.

It is recommended that the piston be heated in

water to 160°-180° F (71°-82° C) if the pin

cannot be removed by hand when cold.

(3) Remove the piston pin (5) by hand.

(4) After the pin is removed, separate the pis-

ton (6) from the connecting rod (7). Tag or

mark the piston and parts with the number

of the bore from which they were taken, so

they may be reinstalled in their respective

cylinders once inspected and/or repaired.

6-29

|