|

| |

TM 5-4210-229-14&P

6-6.

CYLINDER HEAD AND VALVES MAINTENANCE (Continued).

j.

Valve seat replacement.

(1) Remove valve seats with a slide hammer and

expanding screw with pre-cup puller. Two

pre-cup pullers are available for service; one for

intake, one for exhaust valves.

Cleaning solvent (Appendix D, Item 54) is both

toxic and flammable. Keep off skin. Use only

in a well-ventilated area and avoid prolonged

breathing of vapors. Keep away from open

flames.

(2) Clean counter bore (in head) to assure pro-per

valve seat mating and good heat transfer. Use

cleaning solvent (Appendix D, Item54) and brass

wire brush (Appendix D, Item7).

(3) If right fit is not assured between mating surfaces

of valve seat and cylinder head counterbore,

install oversize valve seat inserts as follows:

(a) Take a light cut from bottom in insert

counterbore in cylinder head to dimensions

shown below:

OVERSIZE INTAKE

EXHAUST

INSERT

.002 in

1.998-1.999 in.

1.626-1.627 in.

(50.75-50.77 mm)

(41.30-41.33 mm)

.015 in.

2.011-2.012 in.

1.639-1.640 in.

(51.08-51.10 mm)

(41.63-41.66 mm)

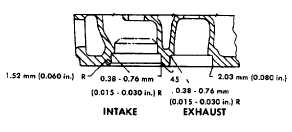

(b) Maintain

radii

shown

when

enlarging

counterbore for oversize inserts.

NOTE

Chilling will prevent metal scraping at

counterbore, ensuring maximum contact

of

mating

surfaces.

(4)

Valve seat inserts installation.

(a)

Chill valve set inserts and driver tool in dry

ice or liquid freon for one half hour before

installing.

(b)

Align insert to avoid cocking.

(c)

Press insert into cylinder head using an

arbor press and insert driver. Exert an

even pressure of 500 ft-lb (2225 N.m) for

five seconds to assure proper seating.

(d)

Insert should be recessed into head when

properly seated.

k.

Coat valve stems with clean engine oil (Appendix D,

Item 36) prior to inserting them from the bottom of the

head.

6- 11

|