|

| |

TM5-4210-229-14&P

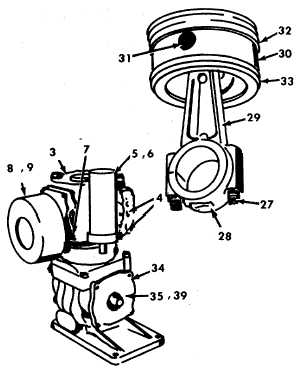

5-20. COMPRESSOR REPAIR (Continued).

t.

Remove piston rings (32 and 33)from the piston

with a ring expander.

u.

Remove four bolts (34) securing the bearing cap

(35) to the crankcase (1).

Do not attempt to pry bearing cap from the

crankcase.

v.

Tap the cap (35) gently with a plastic mallet to

loosen and remove cap.

w.

Remove bearing (36).

Cleaning solvent (Appendix D, Item 54) is

both toxic and flammable. Keep off skin.

Use only in a well-ventilated area and

avoid prolonged breathing of vapors.

Keep away from open flames.

Compressed air used for cleaning or

drying can create airborne particles that

may enter the eyes. Pressure shall not

exceed 30 psi (206 kPa). Wearing of

goggles is required to avoid injury to

personnel.

Never use gasoline, fuel oil or kerosene as a

cleaning solvent.

Be extremely careful to avoid scratching

machined surfaces.

x.

Wash all parts in cleaning solvent (Appendix D,

Item 54). Blow dry with compressed air.

y.

Clean carbon deposits from the cylinder head's

interior surfaces. Clean all interior air and water

passageways.

z.

Remove carbon from piston crowns and ring

grooves. Carbon in ring grooves can be

removed by using a piece of a broken ring as a

tool.

Compressed air used for cleaning or

drying can create airbore particles that

may enter the eyes. Pressure shall not

exceed 30 psi (206 kPa). Wearing of

goggles is required to avoid injury to

personnel.

aa. Blow out all drilled passageways with com-

pressed air to insure they are open.

bb. Remove old gasket material sealer from gas-

ket surfaces.

Removal of crankshaft may cause main

bearing damage. Therefore, inspection

while assembled is recommended.

cc. Examine components for wear, cracks, dam-

aged threads, nicks, scoring and pitting.

dd. Check piston to bore clearance. If clearance

exceeds .008 inch, (.2 mm) the piston (30) and

rod (28) assembly must be replaced.

ee. Check tolerances of components in accordance

with Table 5-2. If components do not measure

within the limits listed, they must be re-

placed.

5-45

|