|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 5-4210-224-14 & P

4-224. CONNECTING RODS REPLACEMENT. (Continued)

the straight ahead position, loosen the adjuster

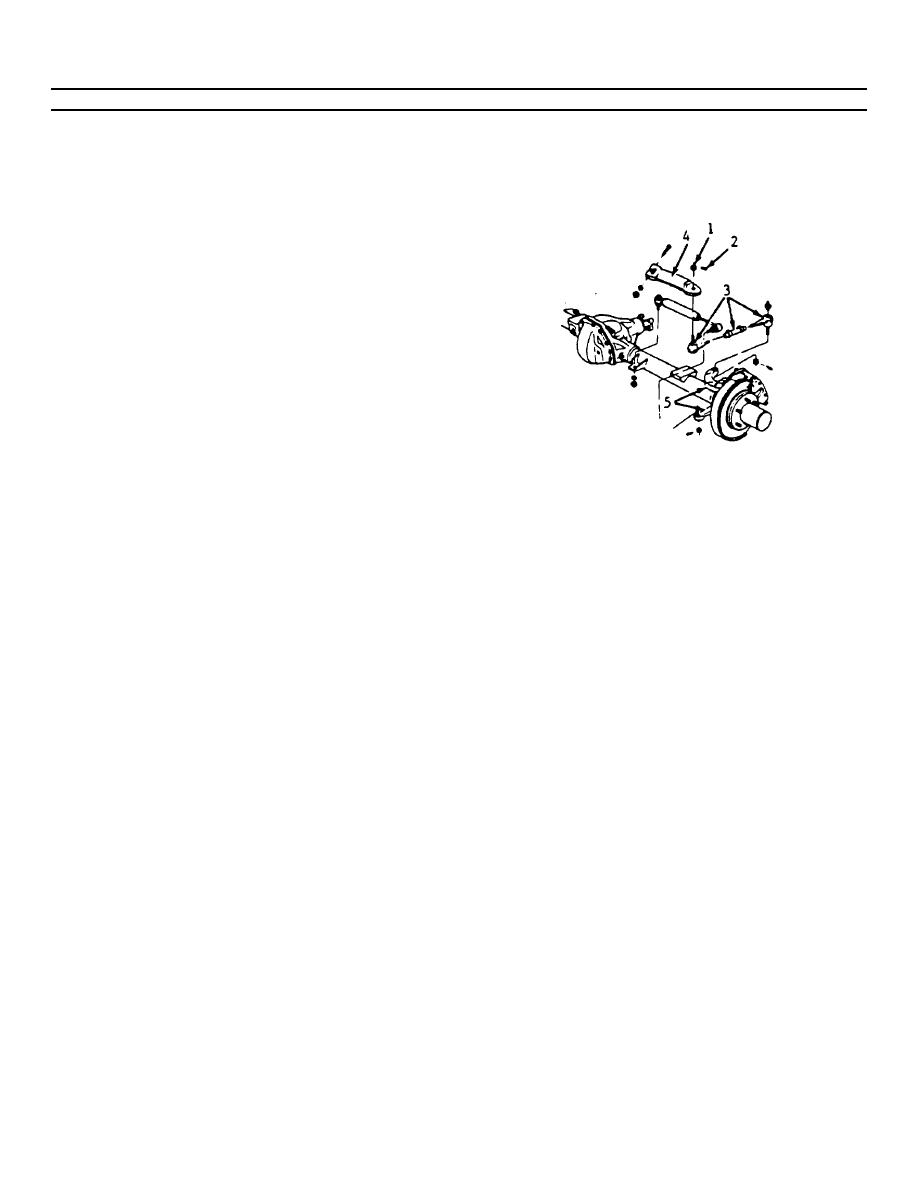

d. Install the inner connecting rod (3) ball stud

tube clamps on the connecting rod (3) and turn

short end to the pitman arm (4) making certain

the adjuster tube to bring the gear back on high

the seal is on the stud.

point.

e. Install the castellated nut (1) to the inner

connecting rod ball stud and torque to 89 ft-lbs

(120 N.m).

f. Advance the nut to align the nut slot with the

cotter pin hole and install a new cotter pin (2) of

the correct size.

NOTE

Never back the nut off to align the

cotter pin hole.

g. Install the outer connecting rod ball stud to the

steering knuckle (5).

h. Install the castellated nut (1) to the outer

connecting rod ball stud and torque to 89 ft-lbs

(120 N.m).

l. Install the adjuster tube clamp bolts. Before

i. Advance the nut to align the nut slot with the

tightening the clamp bolts, be sure the following

cotter pin hole and install a new cotter pin (2) of

conditions have been met:

the correct size.

(1) The clamps must be positioned between

NOTE

the locating dimples at either end of the

Never back the nut off to align the

adjuster tube.

The clamps must be

cotter pin hole. The connecting

positioned within the angular travel

rod ends to the pitman arm and

shown.

steering knuckle must be in correct

(2) Both inner and outer connecting rod ends

relationship to each other after

must rotate for their full travel. The

adjustment, within +/2 degrees.

position of each connecting rod end must

be maintained as the clamps are

j. Set the front wheels in the straight ahead

tightened to ensure the free movement of

position.

each joint.

k. With the front wheels set straight ahead, check

the position of the mark on the wormshaft

designating steering gear high point. This mark

m. Torque the adjuster tube bolts to 40 ft-lbs (54

should be at the top side of the shaft at the 12

N.m).

o'clock position and lined up with the mark in the

n. Lower the vehicle.

coupling lower clamp. If the gear has been

moved off high point when setting the wheels in

4-312

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |