|

|||

|

|

|||

|

Page Title:

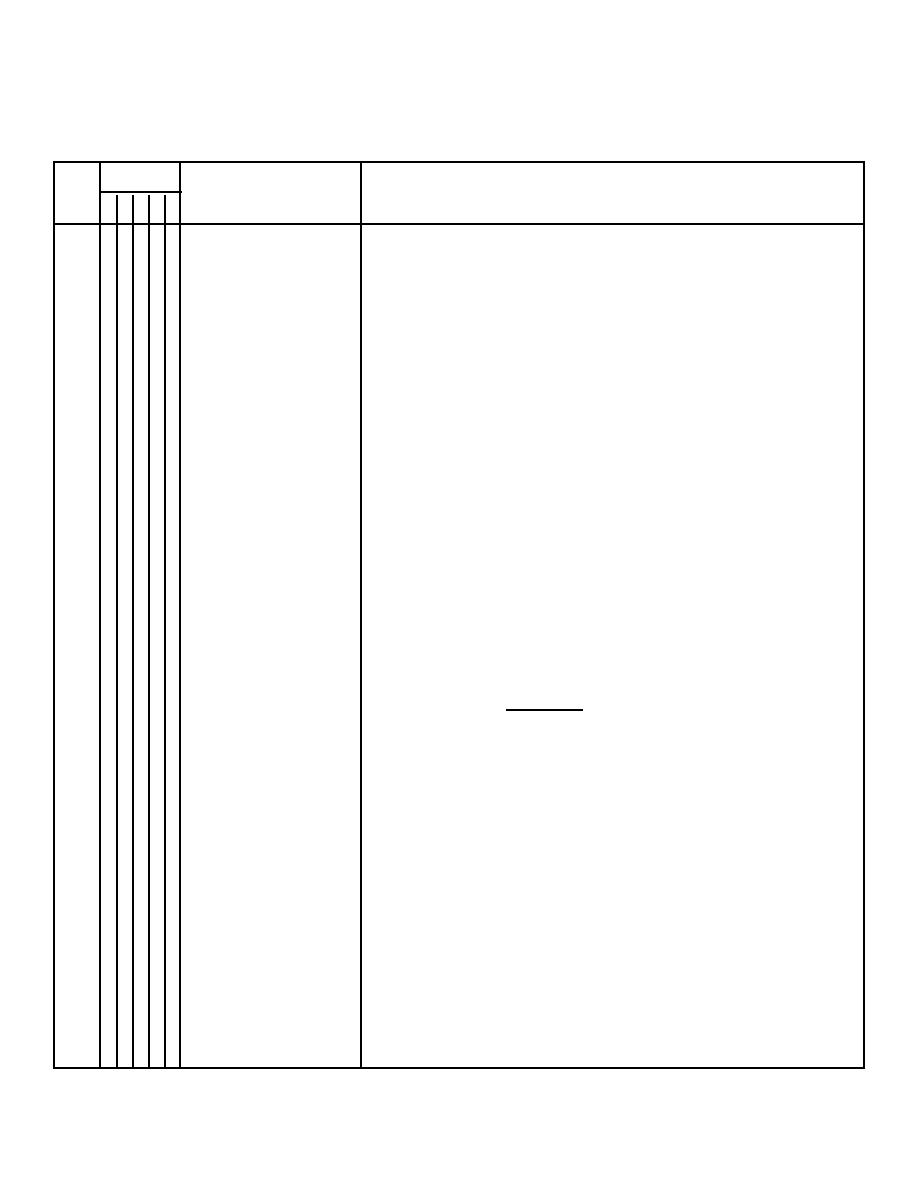

Table 4-2. Organizational Preventative Maintenance Checks and Services (PMCS) |

|

||

| ||||||||||

|

|

TM 5-4210-224-14&P

Table 4-2. Organizational Preventative Maintenance

Checks and Services (PMCS)

W - Weekly

Q - QUARTERLY

A - ANNUALLY

M - Monthly

S- SEMI ANNUALLY

INTERVAL

ITEM

ITEM TO BE

NO.

INSPECTED

PROCEDURE

WMQ S A

HOSE REEL ASSEMBLY

1.

Firehose Nozzle

Visually inspect gasket, bumper, and O-ring for deformation,

q

brittleness, or wear. Inspect baffle on sleeve for structural

damage which might cause a improper spray pattern. Inspect

threads on base and sleeve for damage. Repair or replace

defective parts.

PUMP COMPARTMENT ASSEMBLY

2.

Gauges, Control

Perform operational check on all gauges, control knobs, and

q

Knobs, and Switches

switches. Visually inspect all gauges, control knobs and

switches for damage. Replace damaged or faulty parts as

necessary.

HOSE BODY ASSEMBLY

3.

Lights

Perform operational checks on hose bed pick-up lights, rear

q

warning lights, tail lights, and compartment lights. Inspect

for defective lamps, bulbs, or damaged lenses. Replace de-

fective parts.

FIREFIGHTING SYSTEM

4.

Priming Pump

Perform operational check on priming pump motor. Visually

q

inspect pump for corrosion or structural damage. Replace

priming pump if defective or damaged.

5.

Fire Pump

Perform operational check on fire pump. Visually inspect

q

pump for corrosion or structural damage. Repair or replace

pump if defective or damaged.

ENGINE COOLING SYSTEM

WARNING

Allow engine to cool 15 minutes

6.

Coolant Level

before removing filler cap.

q

Visually inspect coolant for rust or impurities. Check

coolant level. Add coolant as necessary.

7.

Fan Belt

Visually inspect fan belt for signs of cracks, breaks, or

q

wear. Replace belt if any signs of wear are evident.

8.

Thermostat

Visually inspect thermostat housing for corrosion or structural

q

Housing

damage. Inspect the sealing surface for corrosion build

up.

Replace any damaged or defective parts.

9.

Water Pump

Visually inspect the front support bearing for damage or ex-

q

cessive wear. Inspect water pump body for cracks, corrosion,

or excessive wear. Replace water pump if defective or damaged

parts are found.

10.

Radiator

Visually inspect radiator for signs of leakage, corrosion, or

q

other structural damage. Refer to next higher level of

maintenance for repair.

4-7

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |