|

| |

TM 5-4210-220-34

2-12.

PUMP DRIVE AND PTO - Continued

2-12.4 Reducer Gearbox - Continued

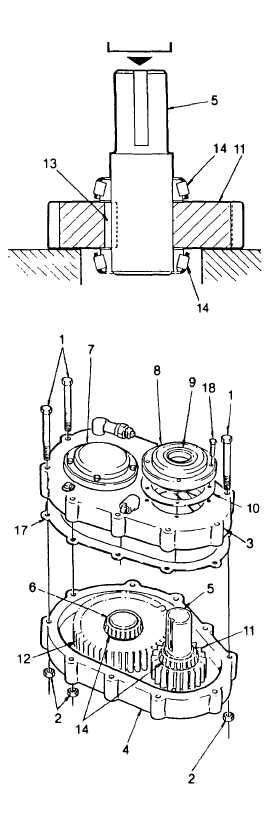

(20) Install the key (13) in shaft (5) key seat.

(21) Position the gear (11) on the press bed.

(22) Support the shaft (5) over the gear (11). Be

sure the drive end of the shaft is up, the

shaft is centered and the key (13) is alined

with the keyway in the gear.

(23) Press shaft (5) into high speed gear (11).

Be sure the gear is centered over the key

(13) so that when the bearings (14) are

installed they butt against the gear and not

the key.

(24) Press bearing cone (14) onto shaft (5) until

it contacts the gear (11). When installing

bearing cone, apply pressure to inner race.

(For low speed shaft only, install spacer

between gear and bearing).

(25) Invert shaft assembly and press other

bearing cone (14) onto opposite end of

shaft (5) until it contacts the gear (11).

When

installing

bearing

cone,

apply

pressure to inner race. (For low speed

shaft only, Install spacer between gear and

bearing.)

(26) If disassembled, press bearing cups into

the open caps (8) and closed caps (7).

Make sure the cap bore is free of dirt so the

cups will seat squarely. Do not install seals

at this time.

(27) Attach one open cap (8) and one closed

cap (7) to the lower housing half (4) using

capscrews (18). Be sure to install three

gaskets (10) under each cap. Tighten

capscrews evenly to 28 ft lb (38 Nm).

(28) Position low speed shaft assembly (6) and

high speed shaft assembly (5) in the lower

housing half (4). Rotate the shafts by hand

to mesh the helical gears.

(29) Position new gasket (17) on lower housing

half (4) and carefully lower the upper

housing half (3) onto the lower housing half

(4).

2-90

|