|

| |

TM 5-4210-220-34

2-12.

PUMP DRIVE AND PTO - Continued

(5)

Inspect clutch discs (39 and 40). Discard any that show signs of overheating. Using a vernier caliper,

measure the thickness of each clutch disc. Discard any that do not fall within specification listed below.

#

Item

ThicknessTolerances

39

Opposing Clutch Disc

.068 .070 in. (1.73 1.78 mm)

40

Bronze Clutch Disc

0605 .063 In. (1.54 1.6 mm)

(6)

Inspect bearings, shafts, and gears as detailed in para 2-7. Make sure oil passage in drive shaft (30) is

not clogged.

(7)

Inspect companion flange splines, seal area, and mounting flange.

(8)

Inspect bearing covers (18 and 29) for cracks, warping or any other damage that may cause oil leaks.

c.

Assembly

NOTE

Lubricate seals and bearings using petroleum jelly (item 21, Appendix B) prior to assembly.

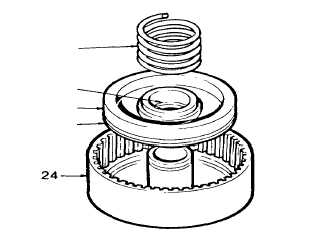

(1)

Assemble spider gear assembly as detailed

in the following steps.

(2)

Lubricate block vee rings (33 and 34) using

petroleum jelly (item 21, Appendix B) and

install onto piston (35). Make sure the

sealing lips of the block vee rings are facing

away from the spring seat.

(3)

Install piston assembly (35) into spider gear

assembly (24). Use extreme care so as not

to damage the block vee rings (33 and 34)

during installation. Twist piston assembly

into spider gear assembly to ensure piston is

fully seated.

(4)

Install spring (36) into spring seat of piston

(35).

(5)

Install retainer (37) onto spring (36) and compress using hand pressure. Lock into position using lock

ring (38).

(6)

Install one opposing clutch disc (39) and then install one bronze clutch disc (40). Continue to install

clutch discs in this staggered manner until all 14 clutch discs are installed. Make sure a bronze clutch

disc is installed last.

(7)

Install clutch stop spacer (47) and lock into position using lock ring (41). Set assembled spider gear

assembly (24) aside.

(8)

Press bearing (22) onto drive shaft (30). Make sure bearing is fully seated against mounting shoulder.

Lock bearing into position by installing lock ring (23).

2-73

|