|

| |

TM 5-4210-220-34

3-8.

ENGINE - Continued

(2)

Clean ring grooves with suitable carbon removal tool. Piston skirt is tin plated and must not be wire brushed

to remove hard carbon deposits. Piston crown is not tin plated and may be wire, brushed to remove hard

carbon deposits.

(3)

Clean inside of crown area, and oil drain holes in ring groove area of skirt Do not enlarge drain holes during

cleaning procedures.

(4)

Inspect tin plating of skirt for scoring, abnormal wear symptoms, cracked or damaged ring groove lands.

Replace if severely scored, damaged, or overheated.

(15)

Inspect crown for scoring or cracked or damaged ring groove lands. Replace if severely scored or damaged.

(6)

Check tapered fire ring groove in crown with tool J24599. Place wire of 0.106 in. (2.692 mm) diameter In

ring groove. Slide wire completely around groove. If the wire is below flush, at any point, piston crown must

be replaced. The 0.100 in. (2.54 mm) diameter wire should be flush or protrude slightly from fire ring groove

of piston.

NOTE

Components of piston assemblies can in certain instances be reused. Undamaged piston pins, crowns, and

bushings that meet dimensional limits for used parts can be reused if installed within the same piston

assembly from which they were removed. The crown, pin and bushing of a cross head piston assembly

should be considered as a matched set. If a crown is replaced, piston pin and bushing must also be

replaced. Similarly, if a bushing needs replacement, a new pin must also be used.

(7)

Check for bent connecting rod, bearing failure causing damage to rod or rod cap, and/or discoloration or

blueing of parts. Replace rod if any of above are found.

(8)

Check for cracks in rods as detailed in para.

2-7.

(9)

Tighten retaining nuts on connecting rod to

70 ft lb (95 Nm).

(10)

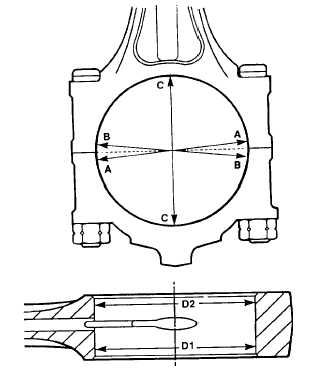

Measure diameter (A and B). The average

measurement of (A and B) is the size at the

split line (X) . X = (A + B)/2.

(11)

Measure diameter (C). The difference in

measurements (X and C) gives the bore

out-of-round measurement; maximum of

0.005 in. (0.127 mm) is

allowable.

Replace rod if not within specification.

(12)

Obtain average bore diameter (Y). Y = (C +

X)/2. Average bore diameter must be

within 3.2495 3.2515 in. (82.537 82.588

mm).

Replace

rod

if

not

within

specification.

(13)

Measure the dimensions (D1 and D2). The

difference between D1 and D2 (taper)

should be 0.0005 in. (0.0127 mm)

maximum. Replace rod if not within

specification.

3-165

|