|

| |

TM 5-4210-220-34

3-8.

ENGINE Continued

(48) Replace all worn or excessively damaged blower parts.

WARNING

Death or serious injury could occur If compressed air is directed against the skin. Do not use compressed

air for cleaning or drying unless the pressure is/has been reduced to 30 psi (2.11 kg/cm2) or less. When

working with compressed air always use chip guards, eye protection and other personal protective

equipment.

(49) Clean the oil strainer in the vertical oil passage at the bottom side of each blower end plate and blow out all

oil passages with compressed air.

NOTE

To install the ring-type oil seal carriers, collars, seal rings, and roller bearings on the rotor shafts and in the

end plates carry out steps 50 thru 58 following.

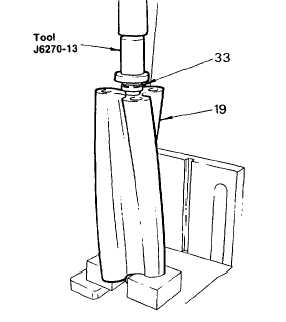

(50) Support one of the rotor assemblies (19) on

wood blocks on the bed of an arbor press.

(51) Lubricate the Inside diameter of the oil seal

ring carrier (33) with engine oil (item 17,

Appendix B). Then start the carrier straight

over the end of the rotor shaft with the

chamfered inside diameter end facing the

rotor.

(52) Place the oil seal ring carrier installer

J6270-13 over the end of the rotor shaft

and against the carrier (33) with the end of

the installer under the ram of the press

Then press the carrier down tight against

the rotor.

(53) Install the remaining oil seal ring carriers on

both rotor shafts in the same manner.

(54) Install an oil seal ring (34) in the ring groove

of each carrier (33) with a pair of snap ring

pliers.

NOTE

To avoid breaking the oil seal rings, do not spread them anymore than necessary to place them over the

end of the carrier. Do not twist the rings or possible distortion may result in loss of side contact area.

(55) Support the blower end plate (3), inner face up, on wood blocks on the bed of an arbor press.

(56) Lubricate the outside diameter of a seal ring collar (35) with engine oil (item 17, Appendix B). Then start the

chamfered outside diameter end of the collar straight into the bore in the end plate (3).

3-117

|