|

| |

TM 5-4210-220-34

3-7 .

TRANSMISSION - Continued

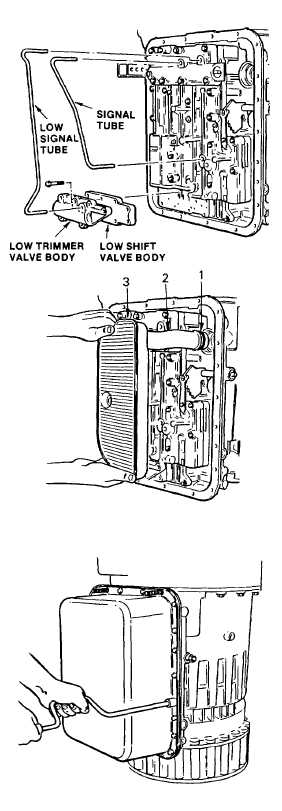

(7)

Install the low shift valve body onto the

lower guide screw. Retain the body

with one 1/4 20 X 2 3/4 in. bolt.

Tighten the bolt to 10 ft lb (13 Nm).

(8)

Install the low trimmer valve. Install six

1/4 20 X 4 in. bolts to retain the trimmer

valve. Tighten the bolts to 10 ft lb (13

Nm).

(9)

Install the signal tube. The signal tube

must be installed into lockup cutoff

valve into the hole near the center of

the valve body. The hole near the end

of the valve body must remain open.

(10) Install low signal tube from low trimmer

valve to lockup cutoff valve.

at.

Installation Oil Filter And Oil Pan

(1)

Lubricate and install seal ring (1) onto

the neck of the intake tube (2) on the

oil filter (3).

(2)

Install the oil filter (3) so the intake tube

and seal ring fit squarely and snugly

into the transmission housing. Do not

twist the oil filter during installation,

push straight inward. Retain oil filter

with one 5/16 18 X 2 3/4 in. bolt, 5/16

plain washer and spacer. Tighten bolt

to 20 ft lb (27 Nm).

(3)

Install two 5/16 18 X 3 in. guide screws

J3387-2 into the transmission housing.

CAUTION

If adhesives or sealers are required to retain the

oil pan gasket, they may be applied onto the pan

mounting flange, but only in the area outside the

flange bed.

(4)

Install a new oil pan gasket over the

guide screws. Aline all holes in

the gasket with those in the

housing.

(5)

To install the oil pan, use twenty-three

5/16 18 X 5/8 in. bolts. Alternately

tighten each bolt, 180 deg. apart, to

approximately half the specified torque.

Final torquing should be 20 ft lb (27

Nm). Pan bolts must retain a minimum

of 5 ft lb (7 Nm) after gasket set to

prevent leakage.

3-82

|