|

| |

TM 5-4210-220-34

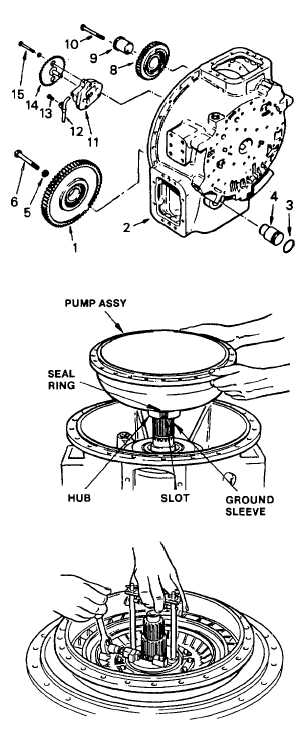

3-7.

TRANSMISSION - Continued

(2) Install the PTO idler gear (8) and spindle

(9). Install the gear and spindle into the

bore near the top of the converter

housing, alining the bolt hole in the

spindle with the tapped hole in the

housing.

(3) Retain the gear and spindle with the 1/2-

13 X 3 1/4 in. self-locking bolt (10).

Tighten the bolt to 97 ft lb (132 Nm).

(4) Install three bolts (15) through holes in

pump drive gear (14) retain scavenge oil

pump (11). Use one bolt (13) to attach

suction tube (12). Tighten mounting

bolts to 32 ft lb (43 Nm), and suction

mounting bolt to 43 ft lb (58 Nm).

ar.

Installation Torque Converter Pump and

Stator Assembly (1) Install torque converter

pump assembly onto ground sleeve. Check

that seal ring is on the hub.

(2)

Pump bearing is a press fit on the

ground sleeve. It may be necessary to

heat hub and bearing area of the pump

assembly to 300 deg. F (149 deg. C) in

oil bath before installation.

(3)

Aline the slots in the pump hub with

tangs in the charge oil pump drive gear

as the pump is being installed.

(4)

Install spacer onto the converter ground

sleeve.

(5)

Place snap ring into tool J26598-A as

follows. Close the jaws of the tool by

rotating the adjusting nut. Place the

snap ring in the tool, under the safety

guards. Position the jaws of the tool in

the snap ring gap. Open the jaws of

the tool by rotating the adjusting nut to

the stop nut.

(6)

Place the fixture, with snap ring over

the ground sleeve. Open the safety

guards to position the snap ring.

(7)

Close the jaws and set the snap ring in its

bore in the ground sleeve. Remove the tool.

3-80

|