|

| |

TM 5-4210-220-34

3-7.

TRANSMISSION-Continued

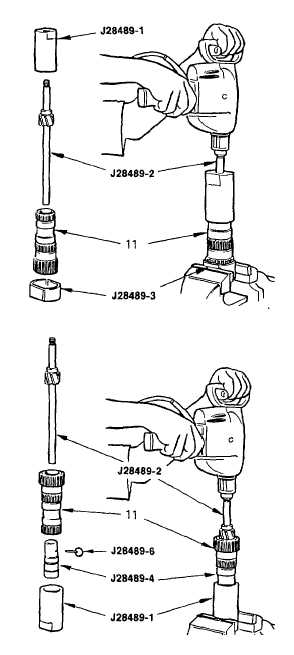

(17)

Using tool J28489, clamp the holding

fixture in a vise. Place the sun gear

shaft assembly in the holding fixture,

and put the reamer and pilot tool in

place.

When machining any bushing, keep reamer at

full drill speed when pulling it back through the

bushing. If reamer is not rotating during

retrieval, it could damage the bushing and

cutting tool.

(18)

Using a 1/2 in. electric drill, machine the

small OD shaft bushing (approximately

75 to 150 rpm) while adding cutting

lubricant (item 8, Appendix B) through

the holes in the pilot tool. If a proper drill

speed

cannot

be

obtained

with

a

standard drill, use a variable speed

control to reduce its rpm.

(19)

To machine the large OD shaft bushing,

clamp the pilot tool in a vise. Insert the

bushing pilot tool J28489-4 into the sun

gear shaft (end with newly machined

bushing) and fasten them together with

the locking pin J28489-6. Using the

same electric drill, engage the shaft of

the reamer in the pilot tool, and machine

the bushing. Add cutting lubricant (item

8,

Appendix

B)

during

machining

operation. Refer to the preceding

caution when retrieving the reamer from

the bushing.

(20)

Check

ID

of

bushings

for

runout.

Runout must not exceed 0.002 in. (0.05

mm) total indicator reading. Surface

finish should be 30 microinch (0.762

micrometer).

(21)

Thoroughly clean shaft of chips and

debris.

(22)

If orifice plug was removed from shaft, use installer J24369 to properly position replacement orifice plug

below chamfer in shaft.

y.

Planetary Carrier Assemblies Inspection And Repair

NOTE

The disassembly and assembly procedures for all planetary carrier assemblies differ only in the proper

tool selection for the specific application and identifies the carrier involved (front, center, rear, low).

3-52

|