|

| |

TM 5-4210-220-34

3-7.

TRANSMISSION - Continued

NOTE

If the fourth-clutch housing is replaced, selection of a proper piston is imperative before seal ring

installation or clutch plate clearance check is done. If the fourth-clutch housing is not replaced and a new

piston is required, make sure the identification letter (M, S, or T) stamped on the new piston is Identical to

that on the old piston.

(11) Place fourth-clutch housing assembly (2) on the work table, flat (rear) side downward.

(12) Before continuing the assembly, the clutch clearance must be established.

(13) Install fourth-clutch piston (11) into the clutch housing. Do not install a seal ring into the fourth-clutch housing

or on piston at this time.

(14) Beginning with an external-tanged plate, alternately install five external-tanged plates (6) and five internal-

splined plates (7) into the fourth-clutch housing (2).

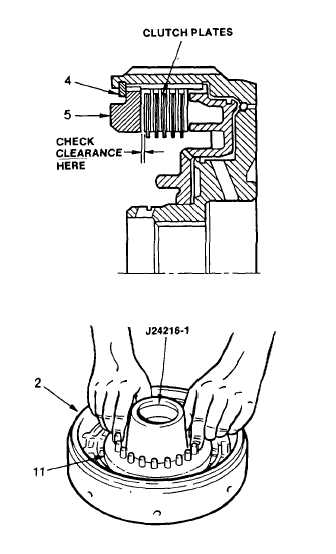

(15) Install the backplate (5) and snap ring (4).

(16) Hold the backplate firmly against the snap

ring. Insert gage J24192 and check the

clearance at the location shown. When

clearance is satisfactory, the thinner step of

the gage will enter between the backplate

and clutch plates; the thicker step will not.

The prescribed clearance is 0.080 - 0.120

in. (2.03 - 3.05 mm).

(17) Remove the snap ring, backplate, clutch

plates and piston from the clutch housing.

When clutch plates are properly selected

for proper clearance, keep the clutch plates

in a pack.

(18) Lubricate with petroleum jelly (item 21,

Appendix B) and install a new teflon seal

ring (13) into the clutch housing. Be sure

the lip of the seal ring is facing the bottom

of the piston cavity.

(19) Place fourth-clutch piston (11) on the work

table, spring bosses side up. Lubricate with

transmission fluid (item 9, Appendix B) and

install

new

teflon

seal

ring

(12),

lip

downward into the groove on the outside

circumference of the piston. A seal ring for

the inside groove in piston (11) is not

required.

(20) Centrally locate the piston in the housing

bore over protector J24216-1. Place the

piston and housing in an arbor press and

apply pressure evenly until the piston is

properly seated.

3-45

|