|

| |

TM 5-4210-220-34

3-7.

TRANSMISSION - Continued

c.

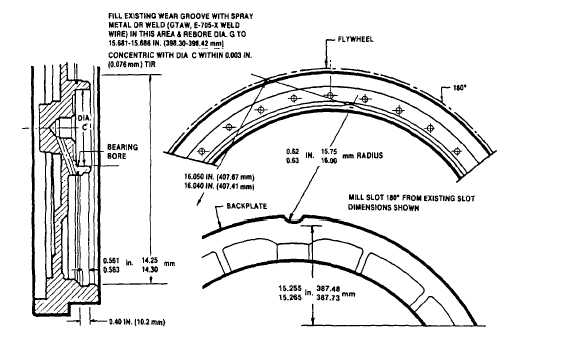

Flywheel Seal Ring Surface Rework.

(1)

Rework the bore and install a sleeve (P/N

6881519) as shown.

(2)

Cool the sleeve in dry ice for at least thirty

minutes before installing. Proper alinement

during installation is necessary to prevent

damaging the bore and sleeve.

(3)

Press the sleeve flush with surface X. Be

sure the internal chamfer is toward the rear

side of the flywheel.

Error! Not a valid filename.

NOTE

Do not attempt this rework procedure unless adequate machining capabilities are available.

(4)

Maximum allowable step wear in the lockup backplate bore of the flywheel is 0.030 in. (0.76 mm).

(5)

If the step wear is less than 0, 030 in. (0.76 mm), refer to the addition of second locking key machining

instructions.

(6)

If the step wear is greater than the maximum allowable wear, refer to welding (or spray metaling) and

machining instructions.

(7)

All new configuration flywheels have two locking keys.

3-12

|