|

| |

TM 5-4210-220-34

2-21.

FRONT AXLE - Continued

(3)

If necessary, adjust the contact pattern by

moving the ring gear and drive pinion. Ring

gear position controls the backlash. This

adjustment moves the contact pattern along

the face width of the gear tooth. Pinion

position is determined by the size of the

pinion bearing cage shim pack. It controls

contact on the tooth depth of the gear tooth.

These adjustments are interrelated. As a

result, they must be considered together

even though the pattern is altered by two

distinct operations. When making

adjustments, first adjust the pinion, then

the backlash. Continue this sequence until

the pattern is satisfactory.

(4)

If the gear pattern shows incorrect tooth

depth contact, change drive pinion position

by altering the shim pack. Used gears

should achieve proper contact with the

same shims removed from the axle during

disassembly.

(5)

If the pattern Is too close to the top land of

the gear tooth, remove pinion shims.

(6)

If the pattern is too close to the root of the

gear tooth, add pinion shims.

NOTE

Check ring gear backlash after each shim change and readjust as necessary to maintain 0.006 0.016 in.

(0.16 0.41 mm).

(7)

If the gear pattern shows incorrect face width contact, change backlash.

(8)

With the pattern concentrated at the toe (too far down the tooth), add backlash, see a. preceding.

(9)

If the pattern is concentrated at the heel (to far up the tooth), remove backlash see a. preceding.

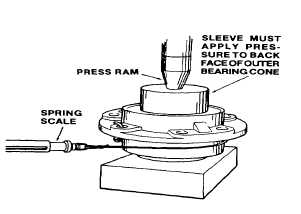

c.

Pinion Bearing Preload Adjustment Preliminary

(1)

Assemble pinion bearing cage, bearings

and spacer (without drive pinion or oil seal).

Center bearing spacer between two bearing

cones.

NOTE

When new gear set or pinion bearings

are used, select nominal size spacer

from the specification chart below. If

original parts are used, use spacer

removed during disassembly.

(2)

With the bearings well lubricated, place the

assembly in a press. Position sleeve so

that load is applied directly to the backface

of the outer bearing cone.

2-299

|