|

| |

TM 5-4210-220-34

(6)

Place the dry part on the third block Do not use lapping powder on this block. Keep the part

flat and move it across the block several times, using the figure eight motion Lapping the dry

part in this manner gives It the "mirror" finish required for perfect sealing.

(7)

Wash the lapped part in dry cleaning solvent (item 10, Appendix B) and dry with compressed air.

2-7.4

General Repair/Assembly Instructions

a.

Truck body

Chassis and exterior painted parts may be resurfaced where paint is damaged or parts have been repaired.

Before resurfacing, scrape off loose and blistered paint. Clean area to be painted by sanding or buffing.

Remove dust. During repair operations, protect bare steel surfaces from rusting with protective oil. Minor

body dents may be removed by bumping with a soft-faced hammer while using a wooden block backing.

b.

Welding

Welding and brazing may be used to repair cracks In steel parts (e.g. brackets, panels and light framework).

Aluminum body panels may also be welded They should only be welded when replacement parts are not

available. Do not weld or braze castings, moving parts, or parts under great stress, except in emergencies

Refer to TM 9-237 for welding practices.

c.

Hoses

Replace all broken, frayed, crimped or soft flexible hoses. Replace stripped or damaged fittings. When

replacing hose clamps ensure hoses are not crimped

d.

Hose Assemblies There are two different styles of hose assemblies. Described below are procedures for

hose replacement.

NOTE

If original hose route cannot be followed at time of replacement, find alternative route and measure for

new hose length.

GENERAL PURPOSE - High Temperature; Hydraulic, Air and Fuel Application.

(1)

Carefully examine both hose end fittings. Discard hose

end fittings if any signs of damage are evident. Proceed

to step 4 following to assemble new hose assembly

using new hose end fittings

(2)

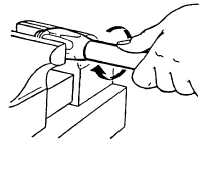

If hose end fittings are to be reused, remove from old

hose. Clamp socket in a vise. Remove nipple from

hose and socket by unscrewing In a counterclockwise

direction.

(3)

Once nipple is removed, Invert hose and reclamp socket

in vise Unscrew hose from socket by turning hose in a

clockwise direction If hose is excessively long, socket

removal is possible by clamping hose in vise and

unscrewing socket from hose in clockwise direction.

(4)

Using a cut-off saw or a fine tooth hacksaw cut new

hose square to length.

2-15

|