|

| |

TM 5-4210-220-34

2-19.

ENGINE - Continued

2-19.10

Oil Pump - Continued

(5)

Remove the screen and cover from the oil

inlet pipe assembly.

WARNING

Dry cleaning solvent P-D-680 (safety or Stoddard’s

solvent) is potentially dangerous. Avoid repeated

and prolonged breathing of vapors and skin

contact with the liquid. Do not use near open

flame, arcing equipment or other ignition sources.

Always

wear

eye

protection

and

protective

clothing. The flash point of P-D-680 is 100 to 138

deg. F (30 to 59 deg. C).

(6)

Wash all the oil pump components using

dry cleaning solvent (item 10, Appendix B).

WARNING

Death or serious injury could occur if compressed air is directed against the skin. Do not use compressed air for

cleaning or drying unless the pressure is/has been reduced to 30 psi (2.11 kg/cm2) or less. When working with

compressed air, always use chip guards eye protection and other personal protective equipment.

(7)

Dry all components using compressed air.

(8)

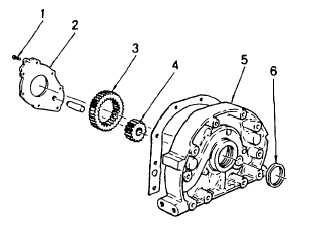

Examine the oil pump gear cavity in the crankshaft front cover. Replace the cover if the surfaces are worn or

scored excessively.

(9)

Replace the driven gear shaft if it is worn or scored excessively. When a new shaft is pressed in place, the

shoulder on the shaft must be flush to 0.020 in. (0.508 mm) below the finished face of the crankshaft front

cover.

(10)

The clearance between the driven gear bushing and the shaft is 0.0010 in. (0.025 mm) to 0.0025 in. (0.064

mm) when new parts are used, or a maximum of 0.0035 in. (0.089 mm) with used parts.

(11)

Inspect the teeth on the oil pump gears and the pump drive hub. Also, examine the bushing in the driven

gear for wear. The bushing is not serviced separately. Therefore, if the bushing is worn, it will be necessary

to replace both the drive and driven gears as they are only serviced as a set. The use of excessively worn

gears will result in low oil pressure which may cause serious damage throughout the engine.

(12)

Inspect the inner face of the oil pump gear retaining plate. Replace the retaining plate if it is scored or worn.

(13)

Reassemble the screen, cover, and oil intake pipe.

(14)

Drive a new 6il seal (6) into the crankshaft front cover (5) using tool J9783 and a hammer. The tool is

designed to drive only on the outer edge of the seal casing to prevent seal damage.

2-234

|