|

| |

TM 5-4210-220-34

2-19.

ENGINE - Continued

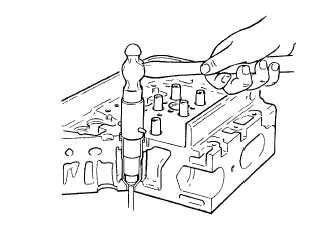

(8) Place installer J5286-4B in new injector

tube. Insert the pilot J5286-5 through the

small opening of the injector tube. Thread

pilot onto installer and handtighten.

(9) Slip injector tube and installer assembly into

cylinder head. Drive carefully into place.

The injector tube upper flange is used to

retain seal. The seal

is accomplished

between

head

counterbore

(inner

diameter)

and outside diameter of tube.

(10) Turn cylinder head upside down. Remove

pilot J5286-5.

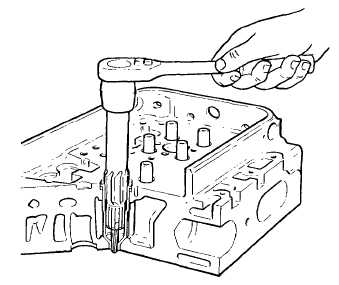

(11) Thread flaring dye J5286-6 onto tapped end

of installer J5286-4B.

(12) Using socket and torque wrench apply 30 ft

lb (41 Nm) torque to the flaring dye.

(13) Remove all tools from injector tube.

(14) Turn cylinder head right side up and clean

injector tube.

(15) Place a few drops of cutting oil (item 8,

Appendix B) on reamer J22525-1. Insert

reamer carefully into injector tube.

(16) Turn the reamer clockwise. Withdraw every

2 turns to remove chips. Keep cutting until

shoulder of reamer contacts the Injector

tube. Withdraw reamer and clean injector

tube.

(17) Turn cylinder head upside down and place

a few drops of cutting oil (item 8, Appendix

B) on cutting tool J5286-8. Insert carefully

into small hole of injector tube.

(18) Remove excess stock from lower end of tube so tube is flush to 0.005 in. (0.13 mm) below the finished

surface of the cylinder head Withdraw cutting tool J5886-8. Clean injector tube.

(19) Insert gage tool J25521 into injector tube. Zero the sled dial indicator J22273 on lower face of cylinder head.

(20) Slide sled dial indicator so its pointer contacts the gage tool. Hold gage tool firmly in injector tube. Dial

should read 0 + 0.014 in. (0 + 0.36 mm).

(21) Place a few drops of cutting oil on the bevel seat of the tube Carefully lower reamer J5286-9 into injector tube

until it contacts the bevel seat.

2-191

|