|

| |

TM 5-4210-220-34

2-13.

FIRE PUMP - Continued

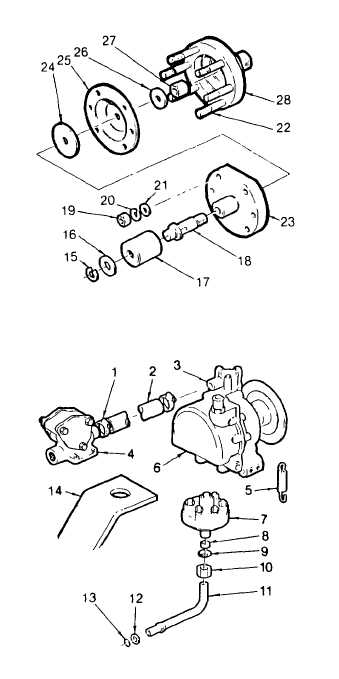

(10) Examine

diaphragm(25)

for

splits,

or

deterioration.

(11) Remove damaged diaphragm (25) from

plunger (18) by removing nut (27) and

washer (26). Make sure to remove

diaphragm plate (24), located on diaphragm

cover (23) end of plunger. Pull plunger from

diaphragm cover.

(12) Inspect diaphragm cover and housing for

cracks, excessive corrosion, or warped

mating surfaces.

(13) Inspect diaphragm housing for stripped

threaded

holes,

and

stripped

water

connection threads.

(14) Inspect

diaphragm

cover

for

oblong

plunger hole.

(15) Examine plunger for excessive wear or

corrosion.

(16) Evidence of damage of any kind is cause for

rejection. Replace component or assembly

as required.

(17) Install plunger (18) into diaphragm cover

(23).

(18) Slide diaphragm plate (24) onto plunger

(18).

(19) Install new diaphragm (25) and washer (26).

Apply a thin coating of pipe sealant (item 22,

Appendix B) to plunger threads. Thread nut

(27) onto plunger and tighten to 24 ft lb (33

Nm).

(20) Aline diaphragm (25) and diaphragm cover

(23)

mounting

holes.

Carefully

slide

diaphragm onto diaphragm housing studs

(22). Secure diaphragm cover to diaphragm

housing

using

flat

washers

(21),

lockwashers (20), and nuts (19). Torque

nuts to 24 ft lb (33 Nm).

(21) Position plastic cap (17) and washer (16) on

diaphragm cover (23) and lock in position

with circlip (15).

(22) Thread disengaging unit (7) into bracket

(14).

(23) Install washer (12) and new O-ring (13) onto

lift-off pipe (11). Position lift-off pipe in

pump head pressure socket.

2-117

|