|

| |

TM 5-4210-220-34

2-13.

FIRE PUMP - Continued

2-13.4

Impeller.

This task covers Repair

TOOLS

MATERIALS/PARTS

Shop Equipment, Automotive

MS178/69 Cotter Pin

Maintenance and Repair,

NSN 4910-00-754-0705

EQUIPMENT CONDITION

Fire Pump Removed from Truck

(see TM 5-4210-220-12)

Volute Body Removed (see para. 2-13.3)

Pump is made of aluminum alloy. Sealing surfaces will be damaged if pry bars or wedges are used to

disassemble components. When reassembling, do not force components into position or use fastener to

bring parts together.

REPAIR

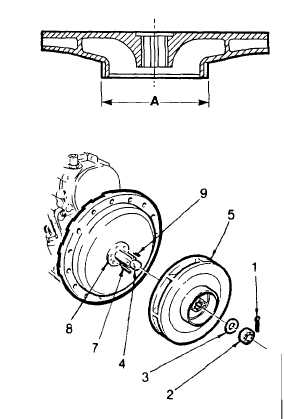

(1)

Measure the wearing diameter of the

impeller in several places. If dimension (A)

is less than 6.975 in. (177.17 mm) at any

of the several points the impeller must be

replaced. If the impeller is to be replaced, it

is recommended that the wearing ring

diameter also be measured. See para. 2-

13.2 for procedure.

(2)

Remove the cotter pin (1), nut (2) and

washer (3). It will be necessary to hold the

drive flange at opposite end of pump shaft

(4) while removing nut (2).

(3)

Remove impeller (5) from splined shaft (4).

(4)

To install, ensure the carbon seal springs

(9) are in place.

(5)

Carefully slide impeller (5) onto pump shaft

(4). Make sure to aline the roll pin (7) in the

impeller with the hole in the spring seat (8).

(6)

Install washer (3) onto pump shaft (4).

Thread nut (2) onto pump shaft and tighten

firmly. Aline slotted nut with shaft hole and

install new cotter pin (1). Bend cotter pin

legs over the nut and toward impeller (5).

(7)

Install volute body as detailed in para. 2-

13.3 preceding.

2-98 (2-99 Blank)

|