|

| |

TM 5-4210-220-12

4-27. TRANSMISSION - Continued

4-27.2 Transmission and Flexplate.

This task covers Replacement

TOOLS

Wires Disconnected (see para. 4-17.10)

Shop Equipment, Automotive

PTO Drive Gearbox and Drive Shaft Removed

Maintenance and Repair,

(see para. 4-17.1)

NSN 4910-00-754-0705

Starter Motor Removed (see para. 4-24.2)

J22582 Engine Barring Tool

Transmission Cooler and Filtration Hoses Removed

4, Appendix G Engine Support Plate

(see para. 4-27.1)

Engine Air Compressor Removed (see para. 4-28.3)

EQUIPMENT CONDITION

All Truck Auxiliary Equipment Removed

MATERIALS/PARTS

Water Tank Drained

4, Appendix E Antiseize Compound

Main Engine Shutdown (see para. 2-10)

14, Appendix E Gasket Eliminator

APU Shutdown (see para. 2-12)

310591 Locknut

Batteries Disconnected (see para. 4-24)

310592 Locknut

All Heat Shields Removed (see para. 4-11)

6885601 Transmission

Transmission Shift Disconnected (see para. 4-12.6)

6882610 Flexplate Assembly

All Drive lines Removed (see para. 4-26.3)

Speedometer and Other Sender

PERSONNEL REQUIRED - 2

NOTE

To allow transmission to be rolled out from under truck, clearance between pump body and

floor must be 32 in. (810 mm) plus the collapsed height of the transmission lifting stand being

used. Calculate height necessary to raise truck to enable transmission removal and

installation. Approximate weight of vehicle could be in excess of 22,000 lb (10,000 kg).

If appropriate truck hoist is available, use as required. If truck hoist is not available, truck can

be driven up on ramps of necessary height or truck may be jacked up front and rear and

safety stands of adequate height and strength placed under front and rear axles.

REPLACEMENT

(1)

Remove

center

bearing

cross

member

frame

assembly

(2)

Be sure transmission and torque converter are drained

of oil

(3)

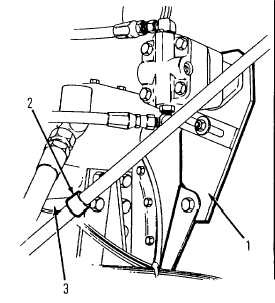

Remove oil level dipstick upper support (2) and

bracket (3) from transmission housing

(4)

Disconnect lower end of dipstick from transmission

pan. Slide dipstick assembly out from underneath

truck

(5)

Using floor jack support rear of transmission, remove

mounting

bolts

attaching

transmission

mounting

brackets to frame brackets.

4-524

|