|

| |

TM 5-4210-220-12

4-22 AIR SYSTEM - Continued

4-22.10 Foot Throttle Valve - Continued

a.

Treadle Repair - Continued

(10)

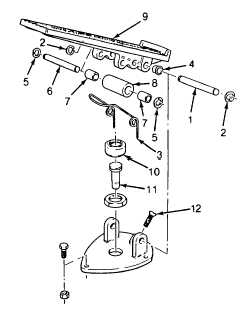

Aline pedal housing holes, valve housing holes and spring (3)

and push pin (1) through all three components. Ensure spring

tends to push pedal up.

(11)

Retain pin (1) with clips (2).

(12)

Ensure roller just contacts the push rod when pedal is released.

Repair stop screw (12) as required, see b. following.

b.

Stop Screw Repair

NOTE

The stop screw is held in position with threadlock liquid.

Replace screw if position of stop requires adjustment.

(1)

Remove screw (12).

(2)

Clean the threads in the mounting plate. Use a tap if

necessary.

WARNING

Dry cleaning solvent P-D-680 (safety or Stoddard's solvent) is potentially dangerous. Avoid repeated

and prolonged breathing of vapors and skin contact with the liquid. Do not use near open flame,

arcing equipment or other ignition sources. Always wear eye protection and protective clothing. The

flash point of P-D-680 is 100 to 138 deg. F (30 to 59 deg. C).

Death or serious injury could occur if compressed air is directed against the skin. Do not use

compressed air for cleaning or drying unless the pressure is/has been reduced to 30 psi (2.11

kg/cm ? ) or less. When working with compressed air always use chip guards, eye protection and

other personal protective equipment.

(3)

Clean the mounting plate and new screw threads with dry cleaning solvent (item 10, Appendix E) and dry

with compressed air.

(4)

Pressurize the throttle valve with at least 65 psi (450 kPa) air pressure either from the truck or from a

temporary air supply.

(5)

Apply a liberal coating of threadlock liquid (item 29, Appendix E) to both the screw and mounting plate.

Install the screw and adjust until the roller (8) just contacts the push rod (11).

4-372

|