|

| |

TM 5-4210-220-12

4-22. AIR SYSTEM - Continued

4-22.6 Air Regulators - Continued

REPAIR

NOT

Valve must be removed from truck

for

repair.

See

REMOVAL

preceding.

(1)

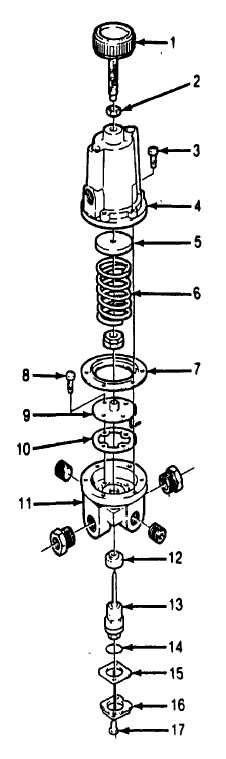

Remove screws (17) from base of valve.

Lift off retaining cap (16) and plate (15).

(2)

Pull exposed hexagon brass portion out of

valve. Whole inner valve assembly is

attached to this piece.

(3)

Remove six screws (3) and lift bonnet

assembly from valve.

(4)

Remove screws (8). Lift out jet tube

assembly (9). Be careful not to bend the jet

tube.

(5)

Remove cork gasket (10).

(6)

Push downwards on the seat ring (12).

Force should be applied to the brass portion

of the seat ring visible from the top of the

regulator. Force ring out of bottom of

regulator.

(7)

Discard seat ring (12) seal ring (14), cork

gasket (10), inner valve assembly (13) and

diaphragm (7).

(8)

Clean all remaining components. Be sure

all foreign matter is removed.

(9)

Coat the outside of the new seat ring (12)

with petroleum jelly (item 21 Appendix E).

Place in body, brass side first. Press into

place being careful not to damage rubber

seal.

(10) Placecork gasket (10) into body (11).

(11)

Install jet tube assembly over gasket, aline

sides and install screws (8) Tighten firmly.

Be sure jet tube is positioned into outlet port

of regulator.

(12) Insert new inner valve assembly (13) into

valve body. Be sure screen is centrally

located in the groove on the topside of the

valve body.

4-356

|