|

| |

TM 5-4210-220-12

4-18. PUMP, PIPING, AND VALVES - Continued

4-18.3 Victaulic Couplings.

This task covers Replacement

TOOLS

MATERIALS/PARTS

Tool Kit, General Mechanic, Automotive,

21, Appendix E Petroleum Jelly

NSN 5180-00-177-7033

75-E-1.5" Victaulic Seal

75-E-2.5" Victaulic Seal

EQUIPMENT CONDITION

75-E-4.0" Victaulic Seal

Main Engine Shutdown (see para. 2-10)

75-E-5.0" Victaulic Seal

APU Shutdown (see para. 2-12)

Batteries Disconnected (see para. 4-24)

All Piping Drained

NOTE

To replace some couplings, it may be necessary to remove the heat shields (see para. 4-11) or

to drain the water tank (see Chapter 2).

REPLACEMENT

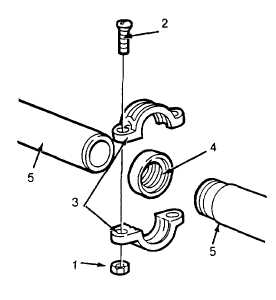

(1)

Remove the nuts (1) and capscrews (2) retaining the clamp halves (3) together.

(2)

Separate the clamp halves (3) and remove. It may be necessary to break the seal between the gasket

(4) and the clamp halves (3) using a small hammer.

(3)

Remove gasket (4) from pipe and discard.

(4)

Clean the pipe ends (5) and inspect for damage such as

indentations, roll marks or projections that might cause

the gasket (4) to leak Replace defective piping as

required.

(5)

Inspect clamp halves (3) for cracks or dents.

(6)

Using petroleum jelly (item 21, Appendix E), uniformly

lubricate the entire gasket (4) and the pipe ends (5).

(7)

Install new gasket (4) onto one pipe.

(8)

Maneuver the second pipe and slide the gasket (4) onto

it. Center the gasket over both pipes (5).

(9)

Position the clamp halves (3) over the pipes (5) and

gasket (4) Ensure the clamp lips lay in the rolled

grooves.

(10)

Install the capscrews (2) and nuts (11) and tighten as

indicated

4-224

|