|

| |

TM 5-4210-220-12

4-15. AUXILIARY POWER UNIT - Continued

INSTALLATION

(1)

Ease flywheel (9) onto end of crankshaft taking care key and socket are alined.

(2)

Install washer (5) and capscrew (6) and tighten to 100 ft lb (135 Nm).

(3)

Install screen (8) and rope pulley (7) on flywheel.

(4)

Install and tighten washers (4) and capscrews (3) to 9 ft lb (12 Nm).

(5)

Be sure gasket (14) is fitted to engine cowling (2).

(6)

Install cowling (2) with six machine screws (1).

(7)

Be sure intake and exhaust gaskets are installed on head studs.

(8)

Install left hand (10) and right hand (13) shrouds over intake and exhaust studs.

(9)

Install washers (11) and capscrews (12).

(10)

Install injector feed line on injector and injector pump Install clamp retaining bolt.

(11)

Install muffler and air intake couplings ensuring intake and exhaust gaskets are fitted between left hand and

right hand shrouds and the couplings.

(12)

Install engine on base, see para. 4-15.1 ASSEMBLY.

(13)

Install APU in truck, see para. 4-15.1 INSTALLATION.

REPAIR

(1)

To replace ring gear, remove flywheel as detailed in REMOVAL preceding.

(2)

Inspect keyway and tapered socket. Replace flywheel and ring gear if damaged.

(3)

Inspect ring gear if teeth are worn or damaged, replace ring gear. See following.

(4)

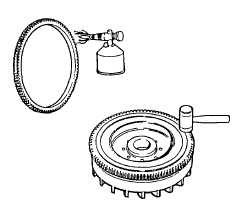

Place flywheel on wooden block so ring gear is

clear of support base.

(5)

Using a large punch and hammer, drive ring gear

clear of flywheel. If it will not break away,

carefully heat ring with gas torch and drive off

when warm.

(6)

Heat new ring with gas torch. Do not allow any

part to become more than blue hot. When evenly

warm, place over flywheel and drive it onto its

seat quickly and evenly using a hammer and

punch.

(7)

Install

flywheel

on

engine

as

detailed

in

INSTALLATION preceding.

4-169

|