|

| |

TM 5-4210-220-12

4-13 PUMP BODY - Continued

4-13.1 Structural Control Panel - Continued

(14)

Pull cable free of APU compartment.

(15)

Unscrew nut (11) and pull cable out of

control panel.

(16)

Install new control cable (10) and attach

to panel using new nut (11) and washer

(12). Tighten nut firmly.

(17)

Route cable into the APU compartment.

(18)

Attach cable to APU fuel shut off lever.

(19

Install APU as detailed in para. 4-15.1.

(20)

Start APU, see para. 2-12 and be sure

engine operates correctly.

h.

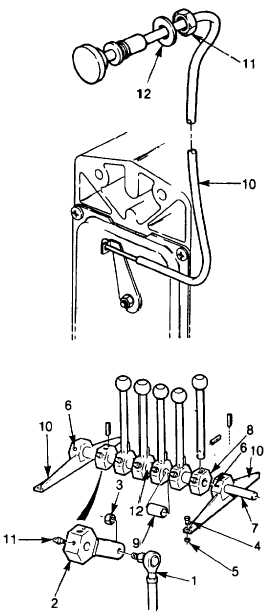

Valve Lever Repair.

NOTE

Control

panel

removed

from

console.

See

REMOVAL

procedure preceding. The valve

control levers are assembled in

two banks which are identical

except for the number of levers.

The repair procedure is the same

for both banks.

(1)

Disassemble tie rod linkages and lever

locks. For each linkage, remove nut (3)

and pull tie rod end (1) free of lever lock

(2).

(2)

Remove four screws (4) and nuts (5)

attaching lever bank to pump body

console.

(3)

Remove lever bank from console.

(4) Loosen two setscrews (6) and remove

shaft (7).

(5)

Inspect lever locks (8). The bore in each lock should be smooth and well lubricated.

(6)

Inspect shaft (7). It must be straight and the surface smooth. Minor surface damage and scratches may

be removed using emery cloth (Item 12 or 13, Appendix E).

(7)

Install shaft locks (8) and spacers (12) on shaft (7) using new and/or old parts as required.

(8) Install control brackets (13) to shaft and tighten setscrews (6).

4-126

|