|

| |

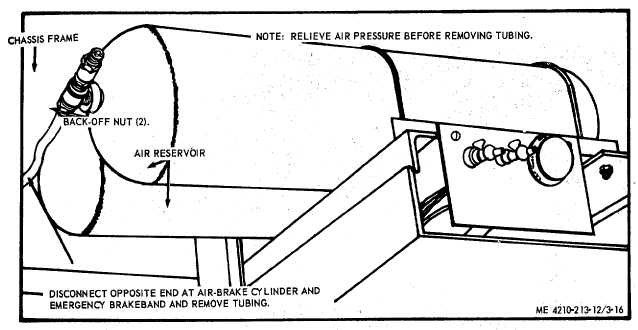

Figure 3-16. Air Tank tubing and fittings, removal and installation.

Section Xl. ELECTRICAL SYSTEM

3-48. General

The electrical system consists of two spotlights, one

mounted on each of the windshield posts, two rear

spotlights mounted on the rear of the fire truck, and

electrical siren mounted on the left front fender, rotating

warning light mounted on the top of the cab. These

lights are waterproof, sealed-beam-type lamps. A

flasher assembly mounted behind the cab instrument

panel functions to interrupt the circuit to directional light

assemblies. A dome light mounted above the left side

control panel furnished illumination for pump operating

controls. A temperature warning light, oil pressure

warning light, and two panel lights are mounted in the

instrument panel on the left side. Two underhood lights

mounted on each side of the front of the radiator furnish

illumination for the engine. Two solenoid relays and

motors, one mounted on each hose reel assembly and

one motor solenoid and motor mounted on the priming

pump serve to furnish power for the priming pump and

hose reels! There are two battery charging receptacles

located at the rear of the vehicle. Two

12 volt batteries and their cable assemblies supply

power to the unit. The temperature and oil pressure

sending units are mounted on the engine. Refer to T M

9-2320-209-10 for the chassis and engine electrical

components.

3-49. Wiring

a.

General. When testing, repairing, or -replacing

the wiring, refer to wiring diagram (fig- 1-3).

b.

Testing. Test a wire for continuity by

disconnecting each end from the components to which it

is connected. Touch' the test probes of a multimeter to

each end of the wire. If continuity is not indicated, the

wire is defective and must be repaired or replaced.

c.

Repair. Shave the insulation on the wire at both

ends of the break and twist the bare wires together and

solder the Connection. Cover the- repaired' breaks with

electrical tape and friction tape. If a terminal breaks off

a wire, replace it, using a like terminal.

d.

Replacement. Replace a wire by disconnecting

it from the component or components and remove the

wire. Install a new wire and attach it to the outside of

the-wiring harness.

3-27

|